TABLE OLIVES PROCESSING 3: CANNING LINES

Totally automatic canning lines for cans and jars are used as the standard in many countries, such as Spain, specially since the 1990´s, where the labour cost has forced the substitution of manual machines for automatic ones.These lines have an average output of 300 units per minute, and in case of the highest level of automatism, it needs only 6 persons to be operated.Among the key machinery needed to provide this level of automatism are:

Totally automatic canning lines for cans and jars are used as the standard in many countries, such as Spain, specially since the 1990´s, where the labour cost has forced the substitution of manual machines for automatic ones.These lines have an average output of 300 units per minute, and in case of the highest level of automatism, it needs only 6 persons to be operated.Among the key machinery needed to provide this level of automatism are:- Automatic depalletizers of cans and jars, where the worker simply places a pallet full of empty cans inside the machine, and the machine disposes the cans in a row inside of the canning line.

- Automatic palletizers of boxes and trays, where the finished boxes are pushed inside the machine, and the machine loads the pallets, even wrapping them when they are full.

- Automatic machines for grouping, carton boxes and trays filling and shrink wrapping cans and jars. In these machines, sealed and labelled cans and jars are pushed inside the machine, and they get out forming boxes or trays.

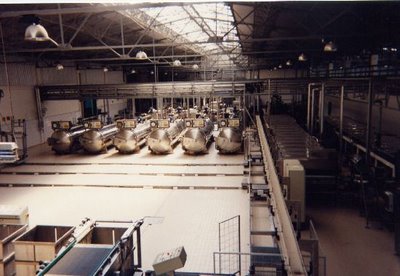

- Lineal pasteurizers, discontinuous autoclaves. In this last case, and in order to create a continuous line with this non-lineal machine, YARKI designs automatic equipment for baskets loading and unloading.

For a lower level of automatism, and an average output of 150 units per minute, some of these machines are substituted by semiautomatic machines. In this case the initial cost of the line is quite lower, but the operation cost are higher. YARKI adjusts their TURNKEY lines to the client demands, taking into consideration factors such as the labour cost of a particular region.

Regarding to the plastic bag canning lines and canning in vacuum or inert gas protection, YARKI designs these lines with automatic equipments, except for the boxes filling process, which is usually made by hand in special boxes forming tables. These tables are designed according to the main machine capacity (bags filling machine).